morfblock.[titanium] 12

€1,815.42 inc. VAT

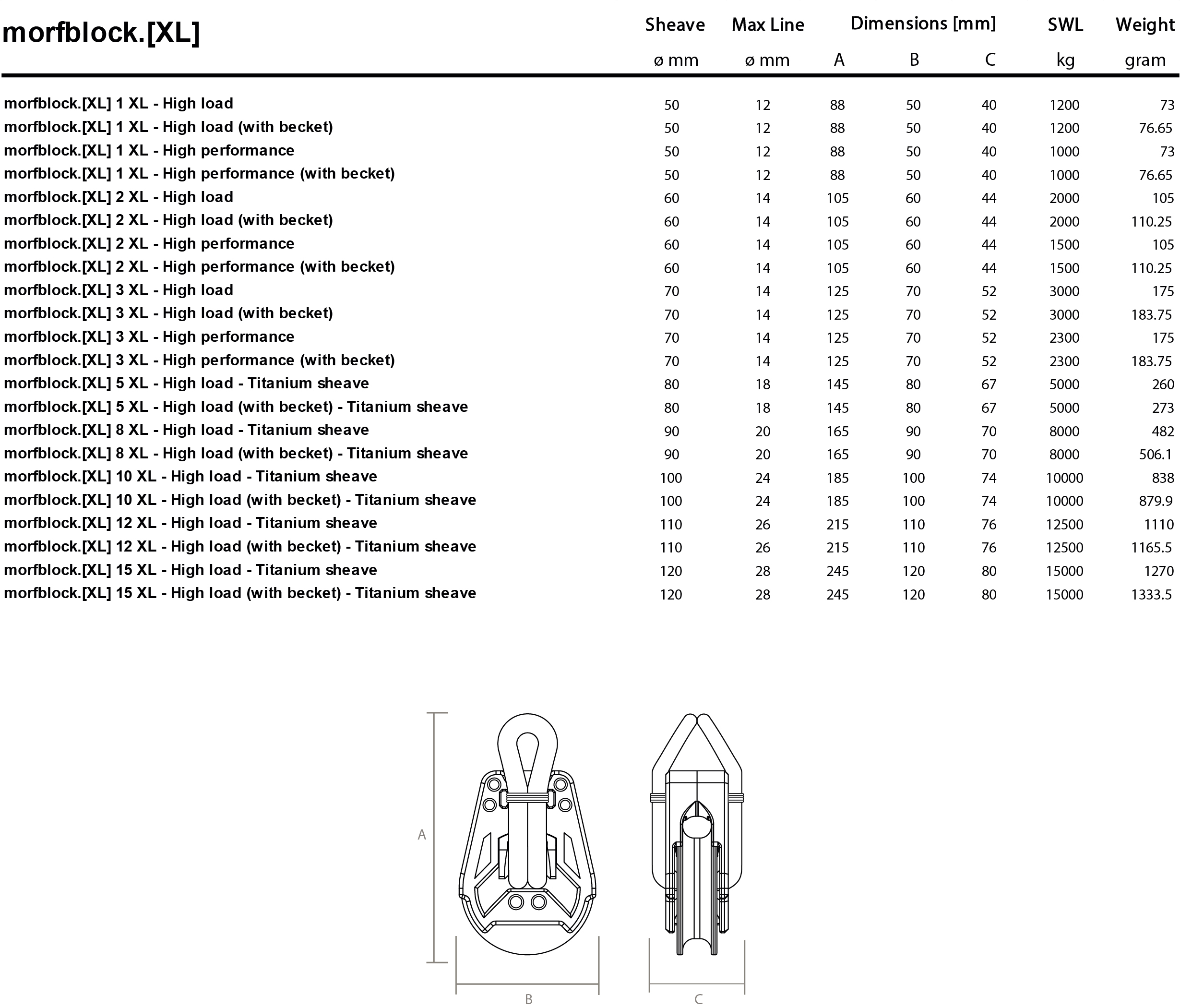

SIZE 12

Titanium sheave + double purpose bearing

- High load + High RPM bearing.

- Large diameter sheave.

- Soft-GRIP Technology.

- Description

- Range

- Block Selection Tips

- Installation & Maintenance

- Downloads

The MORF Block is a light weight and high efficiency block.

MB Cheeks are manufactured by FFF in UV stable plastic; its standard colour is black but it is custom available in a wide range of colours.

MB Bearings are manufactured in high quality thermoplastics. Its patented technology not only provides a low friction media between the rope and sheave but protects its components from ware. High Load bearings are ideal for highly loaded semi-static applications such as: mast base lead blocks, halyard blocks, runners and highly loaded lines. High Performance bearings are ideal for demanding applications such as sheets and control lines where the blocks are in constant movement.

Sheaves are precisely CNC machined in 6082-T6 aluminium with a hard anodise finish. Their size range provides a larger overall diameter, large flange, low weight and incredible load characteristics.

Loops are rigged by MARLOW ropes using a range of Dyneema® SK78, SK99 and chafe covers. The result is a low elongation, light weight, low level of water absorption, high resistance to U.V. rays and low abrasion loop.

SIZING YOUR BLOCK

Working Load

Rope Diameter

SELECT YOUR BEARING

High Load Bearing

Performance Bearing

LASHING & RUNNING LINE

Lashing Rope

Running Line

INSTALLATION

Structural Loop

Lashing your block

Anchor Point

Read carefully and follow installation instructions

MAINTANANCE

Clean

Inspect

Service

Related Products

-

high-Load, morfblock.[titanium], morfblock.[xl], performance

morfblock.[titanium] 15

€2,793.71 inc. VAT -

high-Load, morfblock.[titanium], morfblock.[xl], performance

morfblock.[titanium] 10

€1,535.91 inc. VAT -

high-Load, morfblock.[titanium], morfblock.[xl], performance

morfblock.[titanium] 08

€1,090.09 inc. VAT